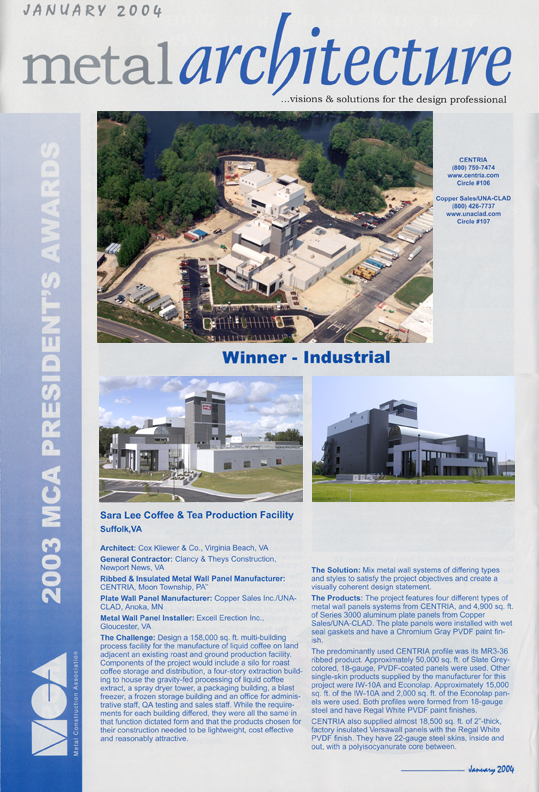

Winner – Industrial

Sara Lee Coffee & Tea

The program for the project defined by Sara Lee Coffee & Tea was the design and construction of a 158,000 ± sf multi-building process facility for the manufacture of their liquid coffee product in Suffolk, Virginia adjacent to their existing roast and ground production facility. The facility was to include a Main Building which included the following components: a silo bin tower for roast coffee storage and distribution, a four-story Extraction building to house the gravity fed process of liquid coffee extraction, a Spray Dryer tower, a Packaging building to house packaging lines, a blast freezer, frozen storage and various utility, refrigeration and storage functions, and an Office building for administrative, QA testing and sales staff. The two-story Utility Building includes process equipment designed to remove water from the waste coffee grounds, which are then fed to a boiler to produce steam used for energy in the process. Also included in the program were small accessory buildings such as facilities for Coffee Ground Storage, Cleaning Material storage and wastewater treatment. The program and requirements for the various components were extremely complex; however, one program requirement was consistent for all – this was to be a building designed around the process.

Metal construction helped Cox, Kliewer achieve the project objectives in several ways. First, metal offered a lightweight cladding material particularly suited for the tower components which would have been structurally problematic with other cladding options (masonry, precast and similar materials). Second, the metal cladding has an inherent flexibility, which allowed us to clad the complex forms dictated by the process configuration. Third, metal offered a cost effective and aesthetically pleasing exterior finish that was uniquely suitable for this industrial facility – as designers, we wanted to showcase the process by providing numerous areas of fenestration where the equipment is visible from the exterior and other interior spaces outside the process areas. Finally, metal offered the opportunity to use a family of products with different characteristics that we were able to combine in a visually coherent design statement.

There were several different characteristics required for the selection of the metal construction products; these resulted in the selection of several different products. First, we were looking for a lightweight metal cladding that had long span capabilities for the tower and the large Extraction building. The 3″ horizontally ribbed panels were a perfect choice. With the prefabricated corners and heavy corrugation, the profile provides a visual interest that is maintained both up close and is not lost from a distance. In the Atrium, which separates the process from the Office portions of the Main building, the 3″ panels are exposed on the inside on the process side to visually identify the function of that portion of the building. We also used 2″ insulated sandwich panels where a vertical spanning element with insulating properties was required. A flat panel was used in the Office area to provide a transition between the heavy corrugated panel and the architectural precast which, with the 3″ panel, was a cladding element used in the Office. In order to provide the Owner with a clean, washable surface, smooth metal liner panels were used attached to the corrugated panels with rigid insulation sandwiched between in the silo bin/spray dryer tower.